WP’s Air Fork: Improved For 2018

In recent years, air-sprung forks have had a chequered run in dirt bikes circles. Well, they have for Japanese bikes anyway. Suzuki, Kawasaki and Honda have all done an about-face with the Kayaba and/or Showa air forks fitted to their motocross bikes, and reverted to a coil-sprung fork in the past year or two. WP’s 48mm “AER” air-sprung fork, on the other hand, seems to have met with more success since it was introduced to KTM’s and Husqvarna’s motocross models in 2015 or 2016. With just one air chamber, WP’s AER fork is quick and easy to adjust, and its performance is widely regarded to be on par, or better, than WP’s much-loved twin-cartridge 48mm fork from a few years back, and way better than WPs 4CS fork that KTM and Husqvarna inexplicably ran on their MX models for a couple of years.

But how has WP’s AER air-sprung fork evolved in the past few years? How much has its performance improved? What’s this WP air fork like to live with, maintain and service? And have KTM and Husqvarna managed to allay consumer concerns about air-fork reliability? We sat down with KTM/Husqvarna Australia’s Technical Services Manager (and longstanding tech guru), Rob Twyerould, to get some answers to these questions, and more…

TM: What was it about WP’s 2017 AER fork that prompted a change for 2018?

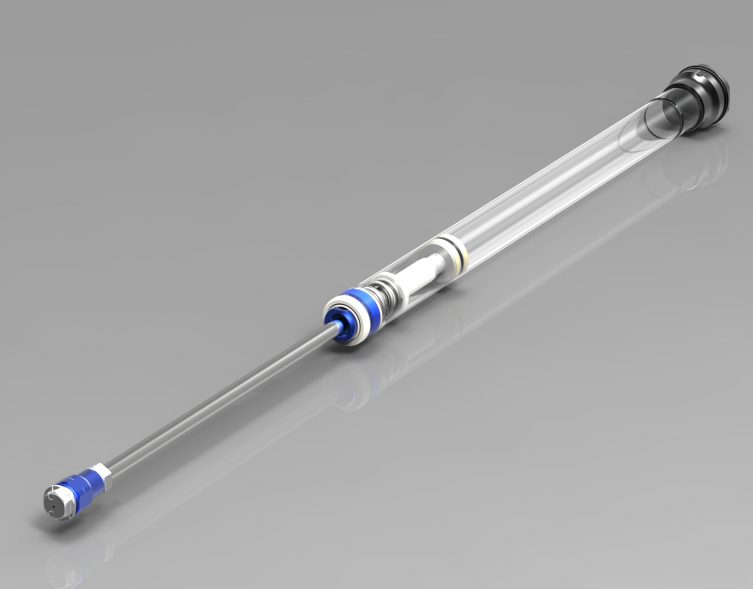

RT: In the AER fork, the pressurised air is all contained in a sealed inner cartridge, with a bypass for the negative chamber that’s enacted at full fork extension – that is, when you go off a jump or sit the bike on a stand in the pits. In other words, if an AER fork does have a fork-seal leak, it will not lose any air pressure. With the 2017 AER fork, that air cartridge’s positive and negative chambers were sealed by an X-ring on the piston (the positive chamber is what’s pumped up using the external Schrader valve in the fork cap). If for some reason (for example, when you compressed the fork to transport the bike) that X-ring failed, you’d end up with pressure on both sides of the piston and the fork would sit halfway down into its stroke. To recover it, you’d have to over-pressurise the positive chamber. Then when the fork extended enough for the X-ring to reach the bypass channel, the pressure would all be pushed back onto the positive side. But in that scenario, you would still need to pull the fork apart and replace the X-ring.

How has the AER fork been modified for 2018 to address this?

For 2018, the piston design has been changed completely. Instead of it using an X-ring, the seal is the shape of a cup. So when you pump pressure into the positive side, it makes the edges of that cup seal against the side of the cartridge. It’s important that the correct grease is used on this new seal, and WP is very specific when it comes to recommending the minimum quantity of grease that needs to be used. If you pull the fork down in the trailer to around halfway and it moves up and down over a period in transit, you can get some bypass on the backside of that cupped seal. But the beauty of this new seal is that once you unload the fork (by putting the bike on a static stand, for instance), the weight of the front wheel will slowly pull the fork back to full extension. And once it’s recovered, it’s good to go. Which means the system is now foolproof. Generally, we’ve only seen this seal bypass issue with brand new bikes. Once it’s been ridden – and the seal and its grease get bedded in – it doesn’t happen again.

Is it possible to prevent the air bypass in the first place?

The trick is to use a fork saver when you tie your bike down to transport it, and I believe that KTM and Husqvarna will soon be supplying one with all models that use the AER air fork. That’s in addition to the special WP pump that comes with the bikes.

Honda, Kawasaki and Suzuki have all dumped their KYB or Showa air forks in the past year or two and reverted to a coil-sprung fork. What impact has that has on consumer’s perceptions of WP’s air fork?

Since the introduction of WP AER air-sprung fork, the feedback has been very positive – both the consumer experience and the product’s reliability and performance. The beauty of the WP AER fork is the simplicity of its design. With only one air chamber in one fork leg, it’s very quick and easy to adjust. With the KYB or Showa air forks you mention, on the other hand, people seemed to get confused about which of the two or three chambers’ pressures they ought to be adjusting. With the WP AER fork, you add air to make the fork firmer and let air out to make it softer. Simple! And even a 5psi change makes a significant change to the feel of the fork. The only thing I see people doing wrong is adjusting the pressure in the fork with the bike still sitting on the ground. Pressures always need to be check and adjusted with the front wheel off the ground. It’s also critical to check and adjust the air pressure with the pump’s fitting screwed fully onto the Schrader valve – so it fully ‘bottoms out’. The models that run this WP AER fork all come with a quality WP pump in their parts kit, and it’s specifically designed with a long thread to make sure there’s minimal bleed-off when it’s being connected and disconnected.

Is adding air pressure to the AER more like preloading the fork or fitting a firmer spring?

It’s definitely like fitting a firmer spring because more air pressure – just like a firmer spring – affects the fork’s overall performance through the entire stroke. The difference with the air fork is that adding more air pressure also affects the end-stroke of the air spring and where the fork settles in its stroke. Remember also that the air spring is more progressive than a fixed-rate coil spring as you compress the fork into its stroke.

In your experience, what’s the biggest difference between air- and coil-sprung forks in terms of feel and performance?

People tend to say that the air fork recovers a little better than a coil-sprung fork. That’s not to say it rebounds faster or in a more lively way, but the ‘destination’ it settles at when extended may be a little taller than a coil-sprung fork. That’s a phenomenon that riders who are new to an air fork need to become comfortable with. Coil springs tend to settle in, and you can run negative preload if you like to make the fork rider lower in its stroke. The air fork, though, will recover to the same height every time. Of course, if this is an issue for shorter riders, they can always let some pressure out. On a kit air fork that WP is currently experimenting with, there’s actually a second valve in the negative side of the air chamber, and adding air to the negative chamber affects where the fork settles in its stroke. It’s a very clever system and a great tuning option for Pro riders, and WP is evaluating whether it’s a feature that’s worth including on their aftermarket forks. But for the average rider, though, it simply adds another level of complexity.

Early air forks suffered from big changes in air pressure as they got hot. Has this been an issue with WP’s AER fork?

Modern-day air forks experience a negligible increase in air pressure, even when ridden hard in hot weather, and/or on tracks with large jumps and deep bumps. With the WP AER fork, most owners report that there’s a warm-up factor involved. In other words, once they’ve set their air pressure after an initial ride, it varies very little during a day’s riding. Our experience is that the pressure in the fork increases slightly in the hands of a fast rider. But the design of the fork allows it to handle that small increase by equalising the increase in the positive side when the fork extends (over a jump, for instance). So if the positive side increases by 2psi, the negative side will also increase by 2psi, meaning the overall fork action will remain similar.

Is there a rule of thumb about what sort of air pressure change equates to a one-rate change in a coil spring?

Well, let’s take Husqvarna’s FX450 cross-country model as an example. The recommended air pressure for riders who are 65-75kg, 75-85kg and 85-90kg is 9.6Bar, 9.8Bar and 10.0 Bar, respectively. So, working off that, you could say that each 0.2Bar change in air pressure (or approximately 3psi, because 1Bar equates to 14.7psi) is equivalent to a change of one spring rate.

Are there any special considerations for the AER fork when it comes to maintenance and servicing?

No. WP’s AER fork is very simple to maintain, service and work on. And seal life is on par with coil-sprung forks.

When do you think KTM and/or Husky will fit WP’s air fork to their enduro models?

Several of both brands’ Pro riders have been testing WP’s AER fork in enduro models, with encouraging results. But KTM’s market research suggests that trail and enduro riders are not yet ready for an air fork because they still value function over performance and adjustability. As KTM’s Product Manager, Joachim Sauer, said at the launch for the new-generation 2017 enduro bikes in Spain, “For trail, enduro, cross-country and desert racing applications, we believe it is still too early to consider an air fork. Consumers do not yet trust the reliability of air suspension when riding in remote terrain, and they do not want to have to carry a pump all day. I think we will need another three to five years for these perceptions to change, and to convince people that an air fork could be an advantage – aside from the weight reduction it offers.” I know that you Transmoto guys have said you think WP’s AER air fork offers many benefits – mainly in terms of weight savings and increased adjustability – and that it will be fitted to the enduro models sooner rather than later. But at this point, I literally don’t know when that will be.

RELATED CONTENT…

TESTED: WP’s AIR- vs COIL-SPRUNG FORKS

Seeing as KTM and Husqvarna introduced two new WP forks in 2017 – the 48mm ‘AER’ air-sprung fork on its motocross and cross-country models, and the 48mm ‘Xplor’ coil-sprung fork on its enduro models – we performed a back-to-back comparison between the two. The idea? To shed some light on the two forks’ comparative performance and versatility, and to get a sense of whether an air fork is likely to soon find its way onto KTM/Husky’s enduro models.

WP AIR FORKS: SORTING FACT FROM FICTION

In response to lingering skepticism about the performance and/or reliability of air-sprung forks, we put WP’s all-new 48mm ‘AER’ air fork through a rigorous test program. The aim? To address the 10 most commonly held assertions – and myths – about air forks, and then sort fact from fiction.

Be the first to comment...