KTM 2Ts: Benefits of Reduced Vibration

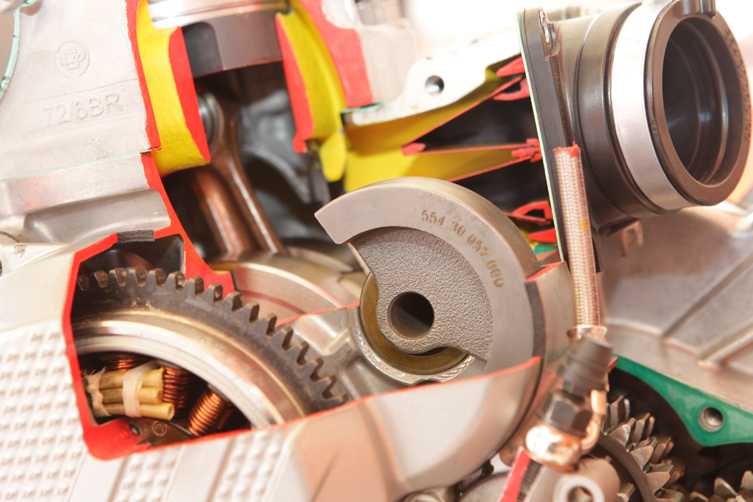

As outlined in our piece about the improvements to the 2017 250EXC’s power delivery, the new-generation 250EXC powerplant generates stronger, broader and more rideable power than its predecessor, but it’s the 50% reduction in vibration levels (thanks to the first-time addition of a counter-balancer) that has created the biggest difference – mainly because it gives the entire machine a much more refined (dare we say, almost four-stroke-like) feel. Interestingly, though, there are other spin-off benefits of this reduced vibration.

According to KTM’s head R&D honcho, Bernhard “Barny” Plazotta, who has overseen the R&D program for KTM’s off-road models for 25 years, the previous two-strokes model’ critical vibration levels created an oscillating effect on the shock spring (which bound up the shock’s action in the first part of its stroke) and accelerated wear in shock bushings, which made them by far the most difficult models to set up. For 2017, however, with vibration levels reduced drastically, they say their two-stroke models’ suspension is now the easiest to get dialled.

Barni: “On our previous two-strokes, vibration created additional wear on things such as the axles and engine mounts. Plus we needed to use a different material in the shock bushings to prevent them wearing too fast. We also had to ensure that a rebound circuit hole drilled into the shock shaft was aligned front-to-rear because our endurance testing proved that the shaft would break if that hole was positioned laterally. None of this is required for the 2017-model two-strokes.”

Barni went on to explain that “When we used a high-speed video camera to shoot footage of the shock spring, we were amazed how much the spring was moving due to that vibration, and we knew immediately that this cannot be good for the shock’s performance and reliability. That footage helped explain why were always struggling to get the shock absorber set-up on the two-strokes. When you enter a set of braking bumps on a trailing throttle, the engine RPMs are in a critical range that tends to ‘bind’ the shock’s action up. Effectively, the vibrating spring prevents the free movement of the shock shaft in the early part of the stroke, which is critical to its performance through braking bumps. So with our previous models, we had to soften the settings to reduce this stiffness, but then that would compromise the shock’s overall performance. Now, with the reduced vibration on the 2017 250 and 300EXC, suspension set-up is easiest on our two-stroke models. Plus we no longer have to use a special shock bushing.”

More on the 2017 KTM 250EXC

2017 KTM 250EXC: 5 BEST MODS

Be the first to comment...