Explained: Mass Centralisation

In design terms, the idea of “centre of gravity” was always about getting weight lower. And that makes a lot of sense when you’re talking about a four-wheel vehicle, where, generally speaking, the lower the weight, the better the thing handles and the less likely it is to roll if you go around a corner too fast, right? Right!

Strangely, centre of gravity is a term that was adopted by the motorcycle industry. And we say ‘strangely’ because the primary objective of motorcycle designers is not to lower a motorcycle’s unsprung weight, but to centralise it. Hence the manufacturers’ adoption – and overuse – of the term “mass centralisation” over the past decade; a design objective widely accepted to create more agile motorcycles by reducing the impact that gyroscopic forces have on handling.

But what does mass centralisation actually mean? How do motorcycle design teams go about achieving it? And would it not be more accurately referred to a motorcycle’s “dynamic fulcrum point”? After all, we’re talking about the axes (that is, more than one axis) around which a bike pivots – from front to rear and side to side, often simultaneously.

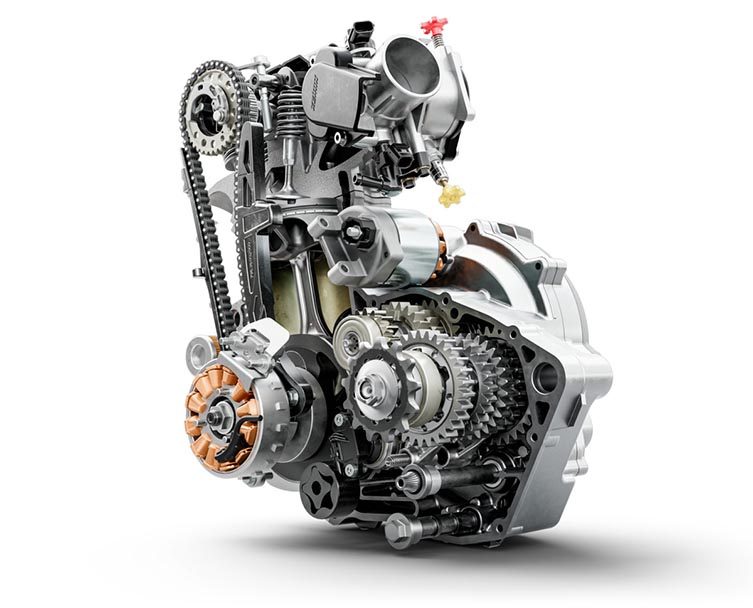

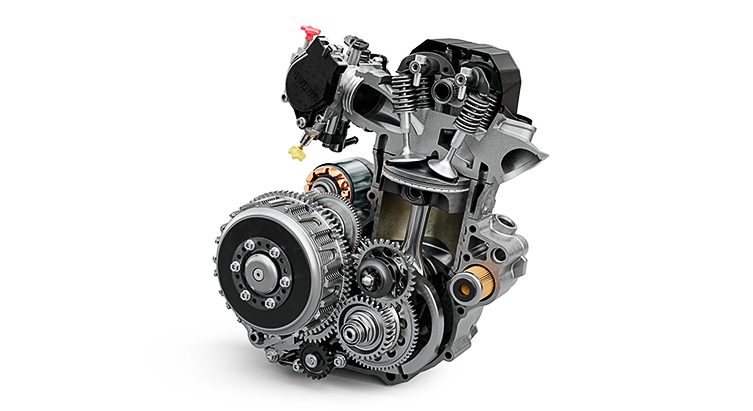

Probably the most obvious year-on-year handling improvement we’ve ever noticed was back in 2016 and 2017, when KTM (and Husqvarna) released their new-generation MX and enduro models, respectively. And there’s no doubt it was a direct consequence of the design team’s obsession with mass centralisation. With the bikes’ lower seat and tank, shorter mufflers and, more critically, the relocation of the engines’ biggest rotating masses (crankshaft and clutch) toward the motorcycle’s centre – or ‘dynamic fulcrum point’ – the gyroscopic effect of all engines was reduced drastically; the result of which was that these new machines could be flicked from side to side or thrown around in the air with noticeably less rider input.

So, to get a better insight into how KTM’s designers achieved these handling dividends, we spoke with the guy in charge of the Austrian brand’s entire motocross and off-road engine development, Michael Viertlmayr…

The concept of ‘centre of gravity’ for motorcycles is now very different to what it was two decades ago. Back then, it was all about keeping weight as low as possible. Nowadays, it’s all about moving the axis of the large rotating masses toward the bike’s centre; toward the fulcrum point around which the bike rotates from front to rear and side to side, right?

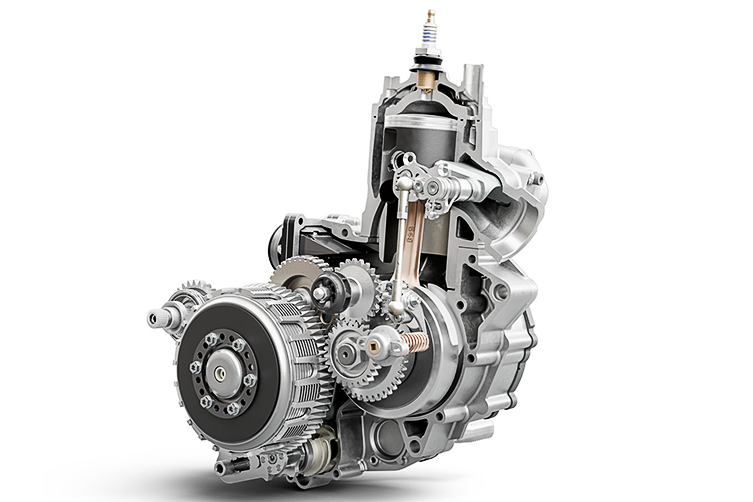

MV: That is true. This fulcrum, or pivot point, is behind the cylinder; somewhere just above the electric starter motor on our bikes. In a corner or in the air, you need to turn a motorcycle around this point. The closer the mass – and especially the heaviest rotating masses – is to this point, the less resistance there is to changing direction. In other words, the less rider input required to change the bike’s direction. Because the rotating masses have the biggest influence on a motorcycle’s handling, that is why we have spent so much time ensuring that we minimise the distance the crank and clutch shafts are from this C of G – or, as you rightly point out it should be called, the fulcrum or pivot point. This is clearly demonstrated by our new-generation 350 and 450EXC-F – these two models have less than 1kg different in static their weight, but they feel very different to ride because the 450’s rotating masses are inescapable larger.

For your new-gen engines, there are big changes in the position of the crank and clutch shafts, designed to radically alter the engines’ gyroscopic forces. Does that design process begin at the crank?

The first step in the design process is to establish what the limits are; how far these rotating shafts can physically be moved. This will be limited by things such as the diameter of the crankshaft, which is defined by the engine’s stroke. The crank diameter then defines the design of the transmission, whose shafts we then move around to find the optimal package. Of course, this is all done in CAD. We then make fatigue calculations to establish whether these dimensions can last in reality. We do several ‘loops’ of this process to get to the point where we think we have a package that looks reasonable in 3D. At that point, it’s time to try the engine in reality and the first prototype is built. We then establish some test variances – things such as different engine layouts, cylinder angles and inertia, the routing of the exhaust, for example – and options for how you can move the engine around in the chassis to give you the optimum position of the crankshaft and output shaft, and so on. It’s a very complex process, so that is only a very broad explanation of how we go about it.

What are some of the ‘extremes’ you went to during the development of KTM’s new-generation engines?

It’s often more useful to take extreme steps to help establish the impact that certain changes will have. For example, we tried several very different positions for the output shaft to properly understand the impact of different relative positions of the sprocket and swingarm pivot. Obviously, this relationship has an impact on how the bike’s rear-end does or doesn’t squat. In the end, we found the optimum was close to what we had already been using in our bikes, but that process gave us a more thorough understanding of the relationship and gave us more confidence in the final design.

But the changes you made to the position of the new engines’ crankshaft and clutch were massive.

Yes, they were radical changes. Moving the axis or position of these shafts by a few millimetres is a lot in engine design terms. For these new four-strokes engines, we have moved them up to 30mm. That is huge. Our objective was to make the triangle of the crankshaft, clutch shaft and output shaft as steep as possible. We then optimised the shifting mechanism so that it could fit under this triangle. In other words, we worked tirelessly to minimise the distance between shafts; to squeeze every millimetre out of the package and create the most compact engines possible. If you keep this modularity between the 250 and 350, and the 450 and 500, I think we are now very close to the limit of what is doable when it comes to minimising engine dimensions.

RELATED CONTENT

KTM TWO-STROKES: ENGINE DEVELOPMENT

KTM’S TWO-STROKE EFI: HOW IT EVOLVED

KTM TWO-STROKES: A BRIEF HISTORY

Be the first to comment...