YOSHIMURA’S AUSSIE REBOOT

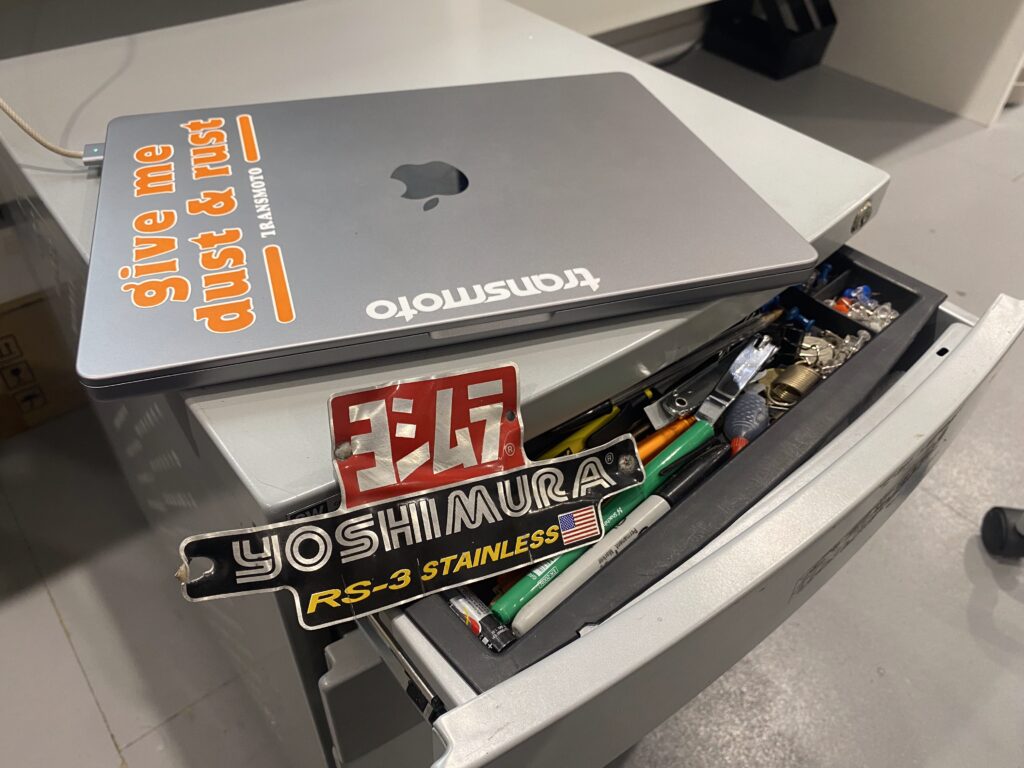

For years, I’ve hung onto a crumpled old stainless-steel Yoshimura exhaust badge. Prior to the cartwheel that ripped it off, this badge was rivetted to the muffler of a 2001-model Suzuki DR-Z400, which I’d converted into a fire-breathing Thumper Nats race weapon back in the day. And ever since that 2001 crash, the badge has sat in my office desk’s top drawer – along with all the other moto mementos, thumb drives and random stuff. But every few years, when I go to cleanse that top drawer of useless clutter, I can never bring myself to bin the badge. But why is that?

“With Yoshimura, you can buy replacement parts to extend its life, and our exhausts are specifically designed in a way that allows the muffler packing and other parts to easily be replaced.”

Having put some thought into that question, I came to the conclusion the badge has sentimental valve because of what Yoshimura represents; what it means to me as a brand. Aside from the fact Yoshi has always been synonymous with precision engineering and craftsmanship and horsepower, this 70-year-old Japanese-born brand – in my mind, anyway – has somehow managed to transcend motorcycle hardware. To me, even Yoshi’s logo has always felt like a curious blend of anima cartoon, obscure math formula (“E=47”), and Japanese graffiti art. Plus, there’s the fact its colourful story is woven into the historic fabric of motorcycle racing worldwide.

So, a couple of months back, when the guys from A1 Accessory Imports, mentioned that they were about to take on the Australian distribution for Yoshimura, and had brought a few key Yoshi personnel out to Oz for an open-house shindig cum product launch at their premises on the south side of Brisbane, I jumped at the invitation. So too did a bunch of Pro racers, industry crew and motorcycle dealers from around the country.

“To me, even Yoshi’s logo has always felt like a curious blend of anima cartoon, obscure math formula (“E=47”), and Japanese graffiti art.”

After meeting Tim Welch and Erick “Big E” Bartoldus – Yoshimura’s Sales Manager and Marketing Manager, respectively – I’m glad I made the trip to Queensland. Cos not only have these two American characters been with the company for many years and know its heritage and product range inside-out; they also struck me as the heart and soul of Yoshimura and personify everything it stands for. Yes, Tim and Big E are living proof of the old adage that any brand is only as good as the people behind it.

At that launch, I sat down with the Tim and Big E for a Q&A session about the iconic brand’s ambitious plans to ramp-up their sales and dealer support in the Australian market. Here are some excerpts from that chat – including a few anecdotes about arguably two of Yoshi’s highest-profile athletes, Australia’s Jett and Hunter Lawrence…

TM: For global context, give us an idea of how Yoshimura Japan, Yoshimura Asia and Yoshimura USA differ in terms of what they produce.

Erick: Each one of those companies focuses on their market segments. Speaking very broadly, Yoshimura Asia focuses on small-bore parts for their Asian Pacific region. Yoshimura Japan makes bespoke hard parts – what we sometimes call “jewellery” as it’s kind of boutique, Gucci-like product [laughs] – for Japan and a little bit of the European market. We – as in, Yoshimura R&D of America – are more mainstream. We make the off-road exhausts for the worldwide markets, and we play a critical role in product development tailored to regulations and performance requirements around the world.

Tim: In other words, we’re making steak dinners; they’re making sushi [laughs]! Probably what’s also worth mentioning here – as many people don’t realise it – is that in addition to exhaust systems, Yoshimura also makes a wide range of hard parts and electrical components.

“It feels right to be partnering with A1, and that’s been echoed by all the dealers who we spoke to here in Australia. It feels like a new era for our distribution here.”

And you two guys have been part of the furniture at Yoshimura in America for a long time now, right?

Erick: Yep, I’ve been here for 13 years.

Tim: And I’ve been with Yoshimura for 18 years – for the first seven years, as the R&D manager before taking on the sales role.

Erick: Tim was fabricating and building exhaust systems for production and racing, plus tooling. Meaning, he’s a sales guy with a very strong technical background in the product.

Why change Yoshi’s distribution arrangements here in the Australian market? It sounds like mindset is key, as I couldn’t help but notice the parallels in the “family-oriented business culture” that both Yoshimura and A1 Accessory Imports speak about.

Erick: Well, it’s an interesting story. The guys from Motorex – which A1 distributes here in Australia – were courting us a few years ago. And they kept pushing really hard to get Yoshimura. I mean, we just kept saying that we were ‘married’ – with Serco, who was our distributor in Australia at that time. But then about a year ago, we made a trip over here to visit a bunch of dealers and talk directly to people about the products, and we decided we needed to make a change to help make Yoshimura product more readily available through dealers. You’re right in saying there is a real affinity with the family culture at both businesses, and as we’ve got to know the A1 guys here, it feels like we’ve known them for years. The people at both companies are very like-minded, to the point we’ll finish each other’s sentences [laughs]. I think it’s testament to what Jason Rogers [A1’s owner and Managing Director] has done in hiring the right people and then letting them do their job. It feels right to be partnering with A1, and that’s been echoed by all the dealers who we spoke to here in Australia. It feels like a new era for our distribution here.

Aside from the fact that Yoshimura is a legacy brand with a 70-year history, what makes it so special? Its engineering excellence? Its renowned craftsmanship? Its racing success? Or something less tangible?

Erick: It’s all of that. But for me, it’s a lot to do with the culture and the people who build the product back in the US. We have about 95 people who are working collectively to make the best product. And we’ve got eight legacy guys who’ve all been at the company for more than 30 years. Now some of their sons work there, and their sons plan to in the coming years. So, when we talk about Yoshimura, it’s not just a brand or a badge on a muffler; it’s about the passionate and talented and experienced people who are making the product every day. We’re not perfect, but we all have a motto that we’ll strive to be the best we possibly can be – and that ethos goes all the way back to Pops Yoshimura, who founded the company in 1954. That way of thinking applies to products as much as it does to what I’m trying to do on the marketing side of the business. I feel it’s a special company because, whatever we do, we’re all about making a very good product and providing a very high level of after-care customer service.

If you talk to Australian dealers who sell any exhaust brand, lack of stock seems to be their common challenge. Why’s that an issue?

Tim: It’s true that everybody suffered with supply issues right through the pandemic – with raw materials, all the way up. And I think that created some complacency whereby people began to be resigned to the next shipment being continually late. But that reality no longer applies. For me, addressing the issue is very simple, and comes down to two things: being able to supply the stock to dealers, and reinforcing the message that there’s also a focus on servicing those exhausts so dealers and their customers know there’s that technical back-up to support them. Prior to the pandemic, there seemed to be this notion that exhaust systems were disposable; like a cigarette lighter that you throw away when it runs out of gas. With Yoshimura, however, you can buy replacement parts to extend its life, and our exhausts are specifically designed in a way that allows the muffler packing and other parts to easily be replaced. The whole idea of our new relationship with A1 here in Australia is about it being an opportunity to re-establish our reputation. We’re putting our money where our mouth is and we’re making a statement that we’ve selected a partner who’s very like-minded and service driven, and we’re here to support that in every way. Critically, we wanted A1 to have a full and complete inventory before we started.

Erick: Just to add to that, I feel the timing is key too. I’m not sure that we, or the A1 guys, would have been ready at this time a year ago. I mean, they were still completing construction on their incredible new premises here in Yatala. But the stars have all lined up now. We’ve planned way ahead to ensure these guys had inventory and could hit the ground running when we pulled the trigger on the distributor changeover. Plus, after seeing how successful the Lawrence brothers have been with Yoshimura for years now, we’ve already had enquiries from race teams here.

Is managing that handover from one exclusive distributor to another a difficult, and sometimes ‘delicate’, process?

Tim: In some ways, yes. As much as we wanted to arm A1 with plenty of inventory before the changeover, we needed to service the existing arrangements at the same time. We didn’t want to shut off the Australian marketplace. Full disclosure: Serco was and is a great partner. We love those guys to death. The difference here is that we needed to shift to a different frequency of business as we had developed a different set of goals.

“Manufacturers will often update valve or ignition timing specs, or change their ECU, or they’ll modify or add an injector. We build a new exhaust system that complements those mods, rather than disregards them.”

“Serviceability” is something you guys have mentioned a lot. Explain the nuts and bolts of what that means with Yoshimura.

Erick: The guys here at A1 have set up a workshop that’s dedicated to servicing Yoshimura product, and we’ve ensured they’re fully trained for that task. Our brand is all about after-care service, so while offering that level of service may sound special – and it is – it’s also at the core of what we do as a brand; making sure that customer satisfaction is there. I think of an exhaust the same way I think of a clutch. You can use it lightly or you can use it heavily. But at some point, it needs to be maintained to keep operating properly. A lot of people don’t seem to understand that. For us, a product’s durability and serviceability are the first considerations of its initial design and development.

Tim: Yeah, and the A1 guys fully understand the importance of that service mindset.

In recent years, has it become increasingly difficult for aftermarket exhausts in general to offer performance gains over the OEM exhausts?

Tim: Yes, it has definitely become more difficult. Prior to my time at Yoshimura, back in 2003, I was working for another exhaust company in an R&D role for their four-stroke exhausts. Back then, you could close your eyes and throw a rock at it, and you’d be able to improve the performance. The aftermarket product and racing and OEs were three legs of a triangle that elevated the production machine’s performance. Back then, a stock 450 wasn’t a 62-horsepower machine; you were lucky to break 50 horsepower. So, collectively, we all raised the level of performance of production bikes. So, yes, it is more difficult these days. But through our racing partnerships with the OEs – and because of Yoshimura’s dedication and the drive to always improve – we’re confident that we can continue to deliver significant performance gains. Also, you’ve got to remember that manufacturers have a calendar date when they need to launch their new motorcycle, which means they have to stop their development process. We, on the other hand, get to keep developing. Also, OEs are developing more than just the exhaust system; they’re developing an entire motorcycle. And that needs to take into account cost analyses and other global market considerations. Meaning there’s a bandwidth and frequency they’re working on. For us, we’re purely focused on that bike’s exhaust system, which gives us more bandwidth and resolution. And that’s the advantage that gets us there.

And with manufacturers releasing new-model machines each year, that’s an ongoing process for Yoshi, right?

Tim: Absolutely. When we get a new bike in, it immediately goes on the dyno because we know that in year two or three (of the typical three-year development cycle), manufacturers will often update valve or ignition timing specs, or change their ECU, or they’ll modify or add an injector, etcetera. We build a new exhaust system that complements those mods, rather than disregards them. That’s a core principle when we update exhaust systems for new model-year bikes. With some other exhaust brands, their primary consideration is whether their pipe fits that new year-model. That’s it! That’s not what we do.

Erick: Just piggybacking on what Tim said, the OEs can only spend so much time developing an exhaust before they have to move on to the rest of the motorcycle. So, when it comes to things like weight, a lot of the OE development stops at a certain point. And I’ve seen a few instances where their stock exhaust is a little lighter than our stainless-steel version. But I can tell you that our system is going to pass sound regs and that it’s more durable than the stock system. And our exhaust has the serviceability that the stocker doesn’t have.

Yoshimura hangs its hat off an impressive tally of 94 major championship wins – across road and off-road racing – so how do the Lawrence brothers’ recent achievements rank in that illustrious list?

Erick: Well, first of all, I have nothing but positive things to say about the entire Lawrence family. It’s infectious how cool they are, and how much we enjoy working with them. Let me give you an example. At the Unadilla round of the Outdoors this year, when Jett wrapped up the championship, everyone’s hanging around the truck. Jett’s not rushing off to go party; he’s hangin’ out. All these media outlets want time with both Jett and Hunter and they’re both willing to talk to them for as long as they want. Anyway, so a handicapped kid rolls up in a wheelchair that has these tracks on it – not wheels, cos he’s off-road, y’know. And Jett goes over there to talk and just hang out with him. They get some photos together and Jett then gives the kid his sunglasses. Jett’s super genuine. He didn’t have to do that. He could have excused himself because a bunch of media was still waiting to talk with him, but he didn’t. I’ve watched him do things like that time after time. He just gives people his time and attention. They both do. Two years prior, when Jett won his first championship on the 450 in 2023, he grabs this kid from over the railing – cos the kid’s dad is holding him up – and then puts the kid on his bike up on the podium. If you’re a fan, can you imagine how cool that would be?! I think it all comes back to the fact that their parents raised them right and taught them the importance of humility and the value of hard work.

Tim: I mean, these guys are on the top of moto’s Mount Everest – and then making a rock pile and standing on top of that – but they are still so grounded. They’re no different than there were when they first came to America. I remember when Jett first came into our workshop a few years ago, all casual and eating donuts and clowning around. And he’s still that same guy, despite all the success he’s had in the meantime.

Erick: And I think Jett is only just getting started. I know a lot of people are, like, ‘He’s going to get bored and jaded’. But, dude, I think he’s going to continue to dominate for the next five years. Easy!

Yoshi has had long-standing and successful partnerships with Suzuki and Honda’s factory race teams. But do those affiliations limit the extent of your involvement – and the exchange of technical info – with other manufacturers? And do OEs ever request that Yoshimura partner with them exclusively?

Tim: You’ve got to remember that, when we signed on to our partnership with Honda, we’d had a 30-year relationship with Suzuki factory racing. We had their factory motocross, factory ATV and factory road racing under the one building and all managed by Yoshimura. So, we couldn’t jeopardize that relationship. But what we did do was make a commitment to both Suzuki and Honda to keep those two families separate; to keep their product development in different spaces so there was no transfer of information between those two biospheres. We also made the point to both brands that the rising technological tide is going to collectively raise all boats. In other words, they each know that what we learn with one may, in theory, be applied to another racing program. But other engine specs and details will not be shared.

Erick: And the development team that’s working on the Honda product, for example, won’t cross streams with another OE brand or its factory racing arm.

Tim: When we were doing Yoshimura Suzuki Racing, JGR and RCH, there were multiple teams working in the same building, but they were completely independent from each other. To answer the second part of your question, about exclusivity, we have been approached by other manufacturers. But when that ‘exclusivity’ stipulation comes up, we just can’t do it. It’s not about us not putting all our eggs in one basket, or our unwillingness to be loyal; it’s simply the fact that exclusivity would stunt the growth of our business. If we were to focus on just one thing, then we’d be devolving, not evolving. And that would be to everybody’s detriment.

For many people, Yoshimura is synonymous with exhaust systems. And that’s primarily what we’ve been speaking about today. Is the emphasis of the brand here in Australia exhaust systems, or will there also be an emphasis on your hard parts and electrical components?

Erick: Well, that’s the beauty of A1 Accessory Imports as a business here in Australia; they have Yoshimura R&D of America at their disposal, plus access to Yoshimura in Japan and Yoshimura Asia Pacific. And by taking advantage of all three companies, they can bring all of those Yoshi product lines into Australia. Given that A1 has a lot of experience with distributing various hard parts, we know they already have an aptitude for it.

Plus, you guys get to travel to Oz a bit more frequently now – which, from what you’ve told me, sounds like you’re up for.

Erick: Absolutely, that’s the case. And we’re already planning our trip back to Australia next September, which will mark the first anniversary of our partnership with A1.

Tim: In the meantime, I believe the A1 guys themselves will be celebrating their 40th anniversary of being in business this coming January. Maybe we need to come back for that party too, Big E [laughs].

WANT MORE?…

For more information about Yoshimura’s history, R&D progams, engineering and tech, product range in Australia, racing achievements and more, click here. Or head straight to A1 Accessory Imports’ website to check out the portfolio of brands they distribute in Australia.

Be the first to comment...