KTM’s Two-Stroke Counter-Balancer

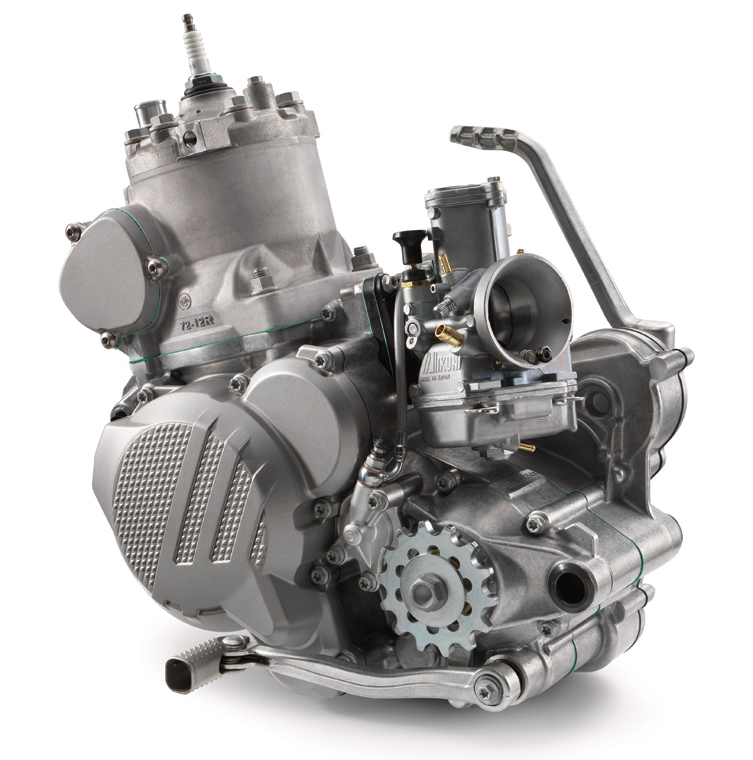

KTM’s 2017 250EXC and 300EXC are the first two-stroke production dirt bikes to use a counter-balancer. We investigate the vibration-killer’s pros and cons.

In the past, any reference to “counter-balancer” meant you were talking about a four-stroke engine. Not any more. The all-new two-stroke powerplants used in KTM’s 2017 250/300EXC are fitted with an ingenious, centrally mounted counter-balancer that reduces vibration levels by an astonishing 50 percent. And these engines proved to be a big hit at the recent launch for the new KTMs in Spain. All of which begs a few questions…

Why has it taken so long for two-strokes to integrate a counter-balancer? What are the pros and cons of fitting one? And why is KTM the only manufacturer to do so on a production dirt bike? To get some answers, we spoke to three of KTM’s most tech-savvy personnel – KTM Austria’s Bernhard Plazotta and Michael Viertlmayr, and KTM Australia’s Rob Twyerould.

WHY SO LONG?

Two-stroke engines have been around for an eternity, and they’ve always been notorious for vibrating way more than their four-stroke counterparts. So why hasn’t anyone joined the dots and fitted a balancer shaft to their two-stroke dirt bike donk? Well, they have – albeit on a bike that never went into production.

Back in 1994, Honda purpose-built an experimental two-stroke for the Dakar Rally, and its engine used a counter-balancer. Impressively, this Honda “EXP-2” finished fourth in the 1995 Dakar at its first attempt, but that was the first and last we ever heard about that machine, or about the use of a counter-balancer in two-stroke engine. So, as far as we’re aware, KTM’s all-new 2017 250 and 300EXC models are the first two-stroke production dirt bikes that have ever been fitted with a counter-balancer.

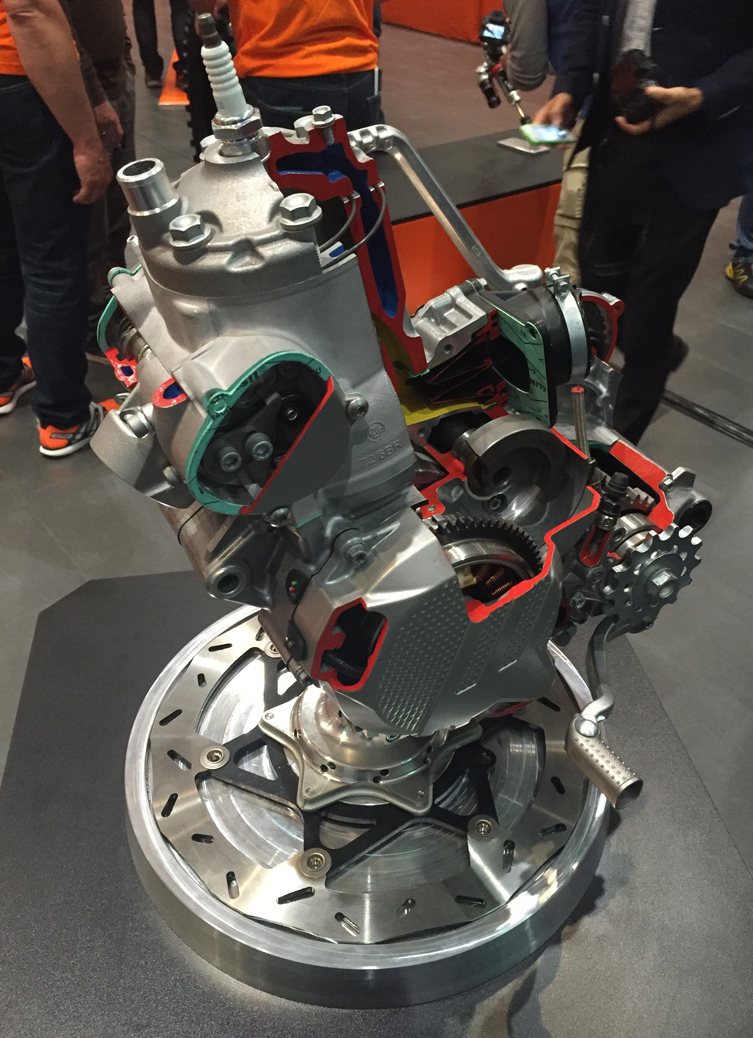

Interestingly, KTM was also mucking around with two-stroke counter-balancers in the mid-1990s. As the boss of KTM’s R&D department, Bernhard Plazotta, recalls, “Back in 1995, we tested a counter-balancer for our two-stroke engines, but we ran into several design problems. Because the engine’s shafts were larger and the air intake was positioned lower, it was not possible to properly fit the counter-balancer into the cases. We decided it was too expensive and complicated and we gave up on the idea.”

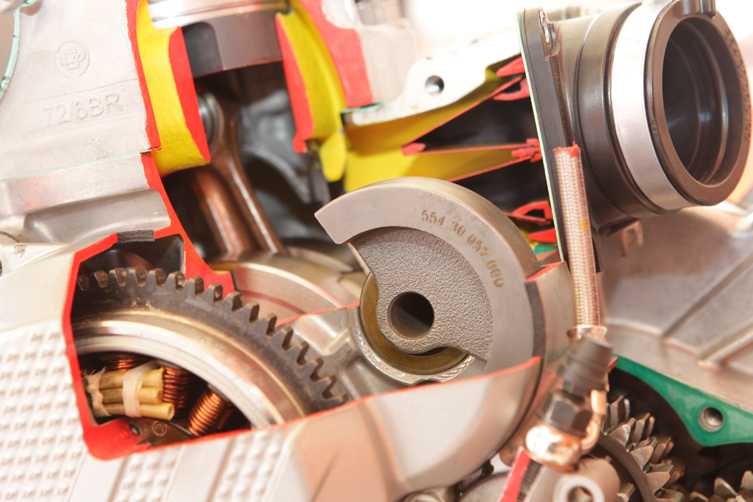

Michael Viertlmayr, who heads up the engine department for KTM’s MX and enduro models, sheds more light on the design’s history. “Like introducing any new rotating mass into an engine, a counter-balancer adds friction and therefore robs the engine of some power,” Viertlmayr explains. “Plus it’s expensive, and it’s not easy to integrate without making the engine’s dimensions bigger. Put simply, these are the issues that manufacturers look to avoid, and I would say that’s why no one has pursued a counter-balancer for their two-strokes up till now.”

Plus, as KTM Australia’s Technical Services Manager, Rob Twyerould, points out, “Introducing another shaft also adds to an engine’s oscillating mass. And minimal oscillating mass is precisely what makes two-strokes so appealing; because the engine has a negligible affect on the bike’s handling. In the past, these costs clearly outweighed the benefits of reduced vibration. However, now that KTM has refined the design and size of the counter-balancer shaft (through its development on the four-stroke range for many years), it became physically possible to integrate the balancer shaft into the 2017 250 and 300cc two-stroke engines in a way where the advantages outweighed the disadvantages,” Twyerould went on to explain.

PROS vs CONS

Michael Viertlmayr confirms that the decision to fit the counter-balancer to KTM’s 2017-model two-strokes came down to a simple cost-benefit analysis. “It got to the point where we believed the compromises in fitting a balancer shaft were more than offset by the benefits,” says Viertlmayr. “And after our very first test with the new engine, we became convinced it was the right solution. In addition to improving rider comfort, reducing the vibration also improved the action of the shock absorber and eliminated the reliability problems we’d had with some parts, such as the shock bushings.”

As Bernhard Plazotta concedes, shock-bushing wear wasn’t the only problem caused by excessive vibration. “On our previous two-strokes, vibration created accelerated wear on things such as the axles and engine mounts, plus we needed to use a different material in the shock bushing to prevent it wearing too fast. We also had to ensure that a rebound circuit hole drilled into the shock shaft was aligned front-to-rear on the two-strokes because our endurance testing showed the shaft would break if that hole was positioned laterally.”

“Now that KTM has refined the design and size of the counter-balancer shaft, it’s become physically possible to integrate the balancer shaft into the 2017 two-stroke engines and reap the benefits.”

But, as Plazotta goes on to explain, the biggest problems the vibration caused centred around the shock absorber’s action and set-up: “When we used a high-speed video camera to shoot footage of the shock spring, we were amazed how much it was moving due to that vibration, and we knew immediately that this cannot be good for the shock’s performance or reliability. That footage helped explain why were always struggling to get the shock absorber set-up on the two-strokes. When you enter a set of braking bumps on a trailing throttle, the engine RPMs are in a critical range that tends to ‘bind’ the shock’s action up. Effectively, the vibrating spring prevents the free movement of the shock shaft in the early part of the stroke, which is very important for its performance through braking bumps. As a result, we had to soften the settings on our previous two-stroke models to reduce this stiffness, but then that would compromise the shock’s overall performance. Now, with the reduced vibration on the 2017 250 and 300EXC, suspension set-up is easiest on our two-stroke models. Plus we no longer have to use a special shock bushing. There’s no doubt that reducing critical vibration by 50 percent improves the entire riding experience, but from a design point of view, you can see that it also has huge implications,” Plazotta concluded.

Didn’t that honda idea get included in all the CRM’s we still have one and it’s so smooth.

What about the wr200. That was a counter balanced 2 stroke that was incredibly smooth. Way ahead of its time.

If it’s so new then why does my 1981 atc 250r have a counter balancer?