BIKE BUILD: JEREMY MCGRATH TRIBUTE YAMAHA YZ250

Mitch Smith is one of those incredibly talented humans; that bloke you know who’s good at bloody everything. Aside from being a former Pro skier and a successful restauranteur, among other things, he owns a business called 74 Works – experts in specialty coatings and vapour blasting.

74 Works is responsible for some amazing builds, including the Project E and the 2022 Yamaha YZ250 – Chad Reed replica. Their latest build is this eye-catching Jeremy McGrath tribute bike, the 2000 Yamaha YZ250. And unsurprisingly, it’s absolutely beautiful. So let’s pass it over to Mitch to fill us in on what it took to create this masterpiece….

THE KING’S MACHINE

Jeremy McGrath’s 2000 Yamaha YZ250 was the bike bike that won the first AMA Supercross series of the Millennium, piloted by the winningest Supercross rider of all time. Jeremy McGrath is, in no uncertain terms, the rider largely responsible for the profile that Supercross now enjoys.

I owned a ‘98 YZ250, which was a very similar machine, and loved it. The YZ was arguably the measure of two-stroke bikes from the late ’90s through early 2000s. And then they made that four-stroke thing, which was also popular…

Watching MC race Supercross was a privilege akin to watching Michael Jordan play basketball – he just dominated. He brought a new level of precision, finesse and style to supercross that was, in my opinion, the pivotal moment for modern technique. This bike represents all of that to me, and is the culmination of dominance for that period.

THE BODY

I found a decent looking donor bike on FB. It was actually quite a find as it is one of a few that was ADR complied back in its day. I believe this was to enable it to be raced in Aussie off-road competition. I bought it sight unseen and had it freighted to us in Mt Beauty.

As is often the case, when the bike arrived, it was less than average, but had good bones. So, the exorcism of filth, neglect and time began. We quickly realised that we’d need to do some frame surgery as she’d done some gymnastics at some point and had a ding that was going to be both visually and structurally no good. There were also the usual dings in the bottom rails.

We got another frame from a wrecker – queue disaster music. The telltale crease in the downtube and stretched welds on the top tube told us that it had a new and not-improved head angle – presumably from its performance in aforementioned terra firma gymnastica.

Enter the third frame … Luke Hamilton is an amazing welder and great friend. He’s also pretty handy on a bike and has an eye for detail. Luke was able to section out the frame and transplant it into the original with skills we mere mortal welding hacks can only dream of. The peg mounts were also built back up and re-bored to accommodate larger diameter stainless pins and bottom rails repaired, along with engine mounts and steering stop.

Having the frame repairs sorted, I was able to look at the swingarm and, again, one of the telltale signs of age with these units is the fretting below the chain slider where vibration, dirt and so on have their way. Fortunately, there weren’t any massive gashes, cracks or stuck chain adjusters so off to Luke it went to be built back up and worked back. Again, the results were nothing short of perfect. We vapour-blasted it, blocked it out by hand to get that OEM brushed finish back into it, and then clear Cerakoted it.

THE BUILD

By this time, Clint Morrison and Todd Beatson, of Morrison Moto Garage, had sifted through the rest of the bike, thrown most of it over their shoulder and started a long list. This bike was never going to be a tarted-up, half-arsed effort; that’s not how Clint and Todd roll, and it’s not how I roll. This bike deserved to be done properly, not cheaply.

- We vapourblasted the engine cases and the boys at MMG built her up

- Cases matched, new OEM 2003-23 crank with Pro-X connecting rod

- New OEM transmission and main bearings

- Hinson clutch basket with OEM hub, pressure plate and clutch plates

- New OEM 03-23 cylinder

- Wossner piston

- Powerflow Engineering worked OEM cylinder head

- V-force reeds and block

- Ciscos power-valve spring

- Pro-Circuit works pipe and custom Pro-Circuit muffler massaged by Luke Hamilton to replicate MC’s Supercross unit

- Carby was vapour-blasted and re-built with new settings and hoses

- Water-pump and other pieces coated in custom Cerakote

- Lightspeed carbon ignition/clutch covers and even some Lightspeed carbon engine mounts from their race stock back-log in their US warehouse – these were special!

- Full new nickel bolt kit from Spec-bolt

THE BLING

We chemically stripped, de-rusted and internally rust treated the frame, then powdercoated it using Prismatic Powders. There are a few haters on powdercoating frames … not to throw anyone under the bus, but if you’re taking your moto gear to an industrial powdercoater who deals with security doors, pool fences and bull bars all day and expecting a good result, you’re probably going to be disappointed. Suffice to say I wouldn’t take my car to a mob that paints houses and expect too much. There is no comparison between good paint and good powder – for durability, finish, adhesion, performance and protection, they’re not even in the same race. But I digress..

The subframe was stripped, vapour-blasted and worked by hand to get as close as visually possible to the titanium unit MC had. I then blued the welds and applied clear Cerakote.

The whole brake system was vapour-blasted and rebuilt with new everything. We used a modern rear master with integrated reservoir, new OEM rear line and braided Goodridge front line, new OEM 270mm front disc, new OEM Brembo rear disc.

The guys at Whitehouse Motorcycles in Albury were able to hunt down an OEM tank, kick-starter, rear brake pedal and anything else Yamaha we needed.

SUSPENSION

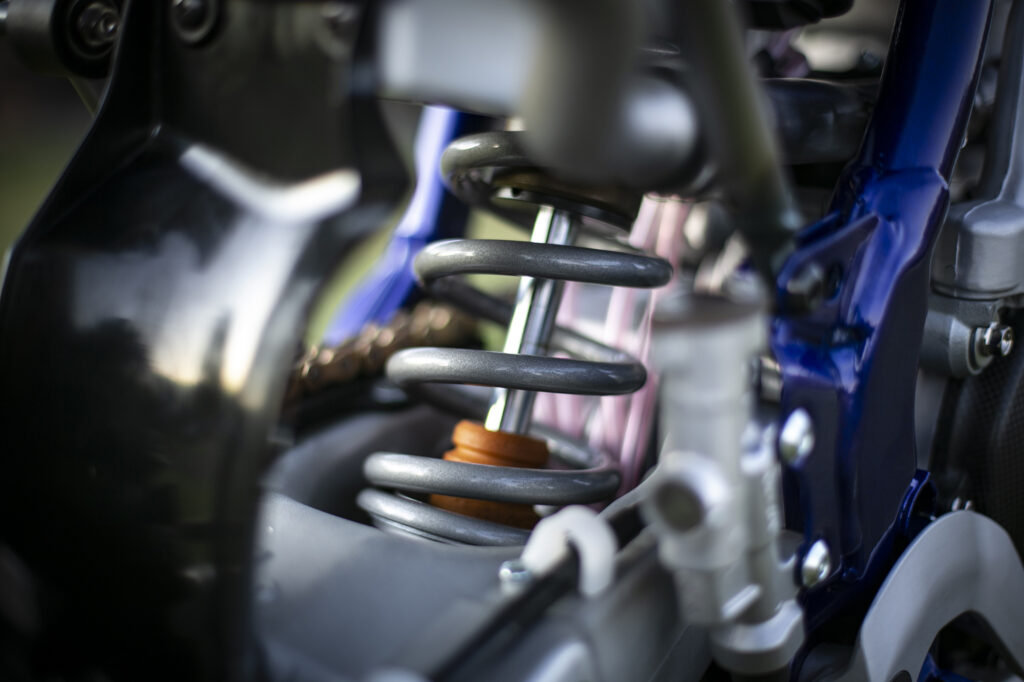

We bought a set of SSS KYB forks and shock from an ‘07 YZ250F. Forks were pulled down and tubes sent off for Kashima Coating by Chad’s Offroad. MMG fully re-valved and rebuilt the fork and shock, shock body/hardware in custom Cerakote, spring in our factory KYB replica powdercoat.

A quick rundown of some but not all other parts:

- Seat cover by Mario at Topline

- Graphics by A-BOMB MX

- Renthal twin wall bars

- Works Connection clutch perch

- Domino throttle

- Custom period-correct EZE triple clamps and billet hubs on new Excel hoops

- Bridgestone tyres

- AFAM sprockets

- DID gold chain

There were dozens of hours spent sourcing parts globally – as mundane as suspension linkages, which are no longer available, but had to be OEM for this build. Every bearing, nut and bolt was replaced.

THE BIG QUESTION

The end result is a bike that is as close as reasonably possible to the genuine article. This isn’t a social media raffle job. We build bikes properly, not cheaply And from a safety standpoint alone, this is really important to both 74WORKS and MMG.

The 2000 McGrath YZ250 tribute replica has been built to ride and admire. I’ll be honest, it hasn’t had a drop of fuel in it nor has the kick-starter been cycled. I constantly war with myself that the bike is too good to ride, and too good not to. It’d be a shame either way!

With the unique wide-ratio gearbox (somewhat similar to today’s YZ250X), engine package and ‘old-man soft’ suspension MMG put in this thing, it’s been set up to do some VMX and gentleman’s laps of your local, but in the classic dilemma faced by all who go down the rabbit hole of a quality build … will it ever be ridden? I think so. It’s just a matter of time and, as one of my mates put it, I’m an orchid and thus only come out when conditions are perfect!

Thanks for reading about my bike. We’re currently working on this bike’s ‘nemesis’ – the 2001 KX SR250 that dethroned it and the King himself. Stay tuned for the 2001 Ricky Carmichael KX250.

Be the first to comment...