BIKE BUILD: YAMAHA WR325 TWO-STROKE

Two-strokes are something that have always been in my blood. Growing up, every bike I owned was a two-stroke, and more specifically a Yamaha. I had owned a few YZ250s through my younger days, as I always loved the versatility of them being a more than capable bike in both the bush and on the track, so it was a perfect bike for me!

As I got older though, it was becoming more apparent that the need for something rego’d was going to be a necessity if I was to keep riding the bush and keep myself out of trouble. Not to mention making life easier, by not loading up a bike each ride. So, the brain was ticking about what was next and the most obvious choice to me was going to be the WR450F. Not wanting to give up the two-stroke heritage though, there were some serious thoughts about jumping the fence to take advantage of the 300cc two-stroke enduro models of other brands. I had even more serious thoughts about why in the world Yamaha wouldn’t hurry up and jump on the 300cc two-stroke train, so I could be first in line for one! This is really where the WR300 (or 325 as it turned into) idea was born.

THE FOUR-STROKE BUG

I had a lot of experience converting Honda CRF frames to re-home CR500 motors through my business, Camesco Fabrications, for friends and customers. So, I knew the project was possible, but I really needed the WR in front of me to make all the measurements and create a list of exactly what was needed to make the dream come alive. So, the decision was made, I would keep the 250 for now and acquired the WR. The first four-stroke I had owned and man what a luxury! Heaps of torque, it tractored up anything, smooth power delivery, in fact I loved it so much that the whole 300 project nearly didn’t come to fruition!

But there was still something missing that I could never put my finger on, until one day, the opportunity arose to swing the leg back over the 250, and there it was.

PROJECT 325

The 325 project was now in full swing. I spent the next 12 months or so measuring and remeasuring, sketching up design ideas, and collecting parts from all over the globe. I wanted to make sure that every possible scenario was worked out before I even loosened a bolt, as I still wanted a bike to ride in the meantime, so I made sure to have all the parts I needed to make the build as seamless as possible.

The first part we sourced was the big bore kit. There’s a few on the market but after a bit of research and speaking with some people with first-hand experience, the 325 big bore kit by Eddie Sanders Racing was chosen as the new top-end. At the time, this was quite hard to source from ESR themselves (as covid was in full swing), but I was lucky to have a contact in the big-bore community who put me in touch with a private sale in the states. The deal was done, and it was beginning to feel a bit more real with the parts on the way.

Still thinking power-plant, and the one thing I knew was essential in making this project the bush weapon it had to be, was the wide ratio gearbox (wouldn’t be a WR without it) which comes in the YZ250X but unfortunately not in the standard YZ motor, I had. Luckily, I found that Rocky Mountain ATV sells a Yamaha wide ratio transmission kit that comes with third, fourth and fifth gears from the 250X, as well as everything else you need to convert it over. Retaining the original 1st and 2nd gears and saving us the hassle of needing to source all the parts individually, this kit was a god send.

SPARKY START

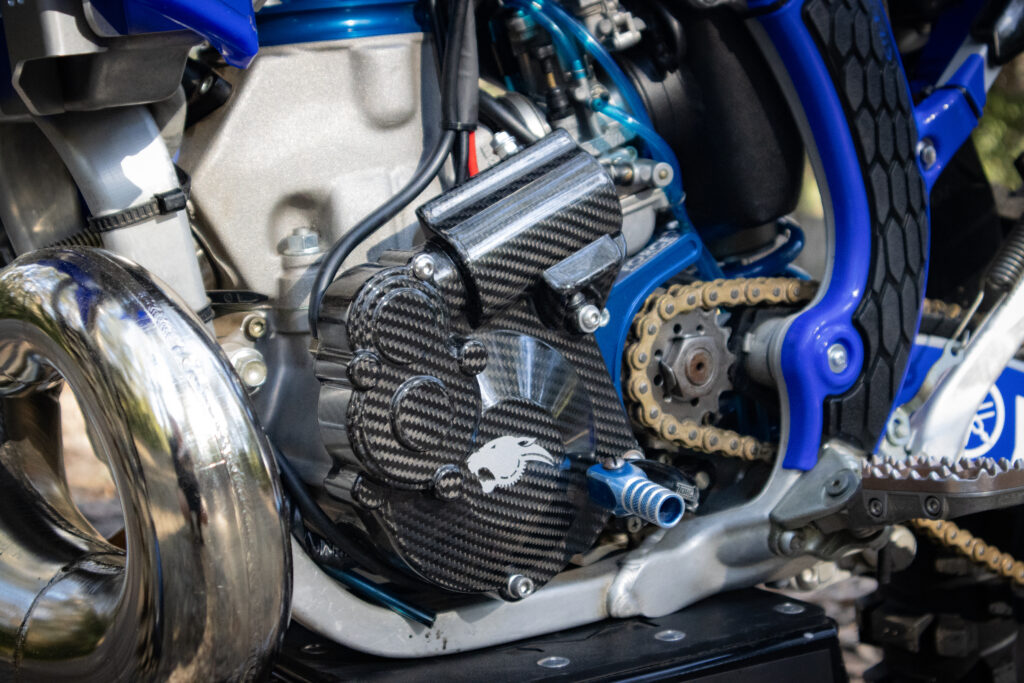

Another major component, and what I found to be the most polarising part of the whole build, was the electric start. After spending a lot of time on the WR, I knew there was no going back to the kick start for me. Not only that, but without the electric start it just didn’t complete the vision of what I dreamt the WR325 would be if it was released commercially. And let’s be honest, when I’m stuck on the side of a rocky, slippery hill side the last thing I want in my mind is ‘how I’m going to kick this thing back into life’. The Panthera Motorsports YZ Electric start kit is one that has had mixed reviews and been the subject of a lot of discussions on online platforms, but without any other options readily available in this category, caution was thrown to the wind!

On arrival, we were blown away by the build quality and engineering involved in putting this kit together. The machined parts all fit perfectly, and it was actually one of the easiest parts to fit of the whole build. After a short amount of testing, we found no faults with any of the mechanical workings of the electric start and it has gotten me out of more than one sticky situation already!

Now, with all the major engine components in our hands it was time to pull the YZ engine out of the frame. From here, it was straight over to Greg James Motorcycles to be completely pulled down for a ground-up rebuild. While we had the cases stripped, I took the opportunity to have them all vapour blasted back to their original beauty. Nothing was left untouched in the rebuild, as well as adding the new components that had been recently acquired. We finally had the heart of the build completed and it was the WR’s turn.

THE POINT OF NO RETURN

As we stripped down the WR to a bare frame, the reality set in that this really was the point of no return. Even though all the calculations had been done and it was now time to put the plan into action, there were still some things that we couldn’t really know until we got into it. Like all previous conversions we had done which involved putting a two-stroke engine into a four-stroke frame, we knew there would need to be a ‘Y’ piece added to the front section of the frame to provide clearance for the expansion chamber to pass through. Drawing inspiration from our CR500 conversions we contacted the team at CP500 (conversionparts500.com) for some advice. These guys produce some of the highest quality conversion parts that we have ever used, including some awesome billet ‘Y’ pieces for their 500 builds, so we thought who better to ask.

Within an email back and forth, we had every dimensioned drawing for all the ‘Y’ pieces they manufactured and after carefully looking over each one, we found something that we thought we could make work. This part alone made our job 100 times easier and I can’t thank them enough for being completely open to sharing their knowledge with us to get us this solution.

With the first major hurdle of the frame work cleared it was time to make the first cuts. I could only put it down to some solid preparation for this day (maybe a bit of luck) but it was smooth sailing at this point. Within an afternoon we had the ‘Y’ piece fitted, new lower engine mounts fabricated and finally a look at the new heart sitting perfectly in its new home. Almost too perfectly! Everything seemed to line up, the angle, the heights, the spacings, like it was just meant to be. This was a great motivation for the next steps as we knew we weren’t out of the woods just yet. From here the head stay mounts had to be manufactured with a new crossmember added within the frame to support a stock style bracket which we had laser cut with our logo in it. We spent a lot of time trying to make things look as factory as possible with an overall goal of a ‘straight off the showroom floor’ look that we were going for. These pieces completed the engine mounting and now it was time for the real challenge.

BREATHIN’ EASY

The airbox. A lot of our R&D was focused on this part in the lead up to the build, as we knew it would be the ‘make or break’ for the whole project. Yamaha started moving towards the reverse cylinder engine around 2010 with the YZ450F with the WR implementing the same technology soon after. This means that the exhaust exits from the rear of the cylinder and the air intake breathes from the front, placing the stock WR airbox up near the handlebars (where a traditional fuel tank would be) instead of at the rear of the bike like most other models. The YZ two-stroke engine is the exact opposite, and to make matters worse, the air intake and carby line up directly with the rear shock reservoir.

With these parts now in place we got to work creating a one-piece, full aluminium, air box and intake pipe to marry up the carby with the stock front mounted airbox of the WR. Machined adapters were made to connect both ends of the air box in place, then we cut and shut everything in between.

The airbox hugs around the rear spring and uses all the available space possible to get the volume of air that the big bore would need. It’s a unique shape, but one that proved to be flawless in testing, which was a bonus.

With the textured black powder coat applied a lot of people are shocked when you tell them it’s a fully aluminium airbox. It seems to blend in well with the whole build, again trying to keep the factory look alive!

From here we were on a roll with what seemed to be the big issues out of the way. We modified the radiators to suit the YZ cooling system, fabricated exhaust and expansion chamber brackets for the new Pro Circuit system and set to work fitting the new Rtech plastics and OEM accessories, along with a few trick bits for good measure. Moto Kit added the finishing touches to the body with a sticker kit that absolutely took the whole project to the next level, tying everything in with an epic factory look.

With the main body of the bike fully assembled it was off to Motolab to tune the suspension and get that big bore power to the ground. This was a critical and mostly overlooked part of getting the bike to work for, not against, you, and it was something we knew we had to get right, especially with the handful we were creating! At this point, AP Auto Electrical was also performing some wizardry on the stock wiring loom, taking out the excess wiring that we didn’t need and integrating the parts we did so that we could keep the stock dash, switches, indicators etc.

With the last components complete we finally got to stand back and look at the bike as a whole. It was a crazy feeling to finally stand in front of the bike that was just a dream only months before. It was getting close to midnight as we finished bolting the last parts on but that wasn’t going to stop us hearing what our hard work had created. The bike rolled out of the GJM workshop finally back on its wheels and with a quick tap of the button, the WR325 came to life! Filling the night air with the sweet sound and smell of two-stroke. This moment made all those long nights and months of planning suddenly feel worth it.

TESTING TIMES

The next day was testing, and it was definitely the most anticipated part. My main concern was whether the frame modifications would change the way the bike handled, as well as how the new engine would perform at high revs with the custom air box. The same as it had the night before, a quick tap of the button and the WR325 was awake and eager to get after it. All previous worries were forgotten as I hit the first corner and was pleasantly surprised that nothing had changed in the way of handling; still the same trusted WR ergonomics railing the corner with ease. Feeling more than comfortable already, I wound on the throttle mid-corner and held on for dear life as the tyres gripped the dirt. The power was smooth and broad down low with miles of torque at my fingertips, followed by a powerband that hit like an absolute freight train.

You couldn’t wipe the smile off my face for the rest of the day. The Yamaha WR325 was everything I had hoped it would be, and it was finally reality. The fact that we could make it work, and work so well is a testament to everyone involved in this project and I thank you all for your efforts. Now to get the hours on it and really put it through its paces!

Be the first to comment...