DESERTX RALLY: SUSPENSION BACKSTORY

Lead test rider for Ducati’s DesertX models, Matteo Graziani, reveals the fascinating story behind the development of the top-shelf, MX-derived Kayaba fork and shock that comes on the all-new DesertX Rally model.

In a general sense, you wouldn’t say that Italian and Japanese cultures were particularly alike. In fact, in motorcycle design circles, the two seem almost diametrically opposed. But when it came to developing Ducati’s race-bred DesertX Rally model, the unlikely collaboration between the engineers from Ducati and Kayaba produced a machine whose off-road capabilities arguably set a new benchmark for adventure-tourers.

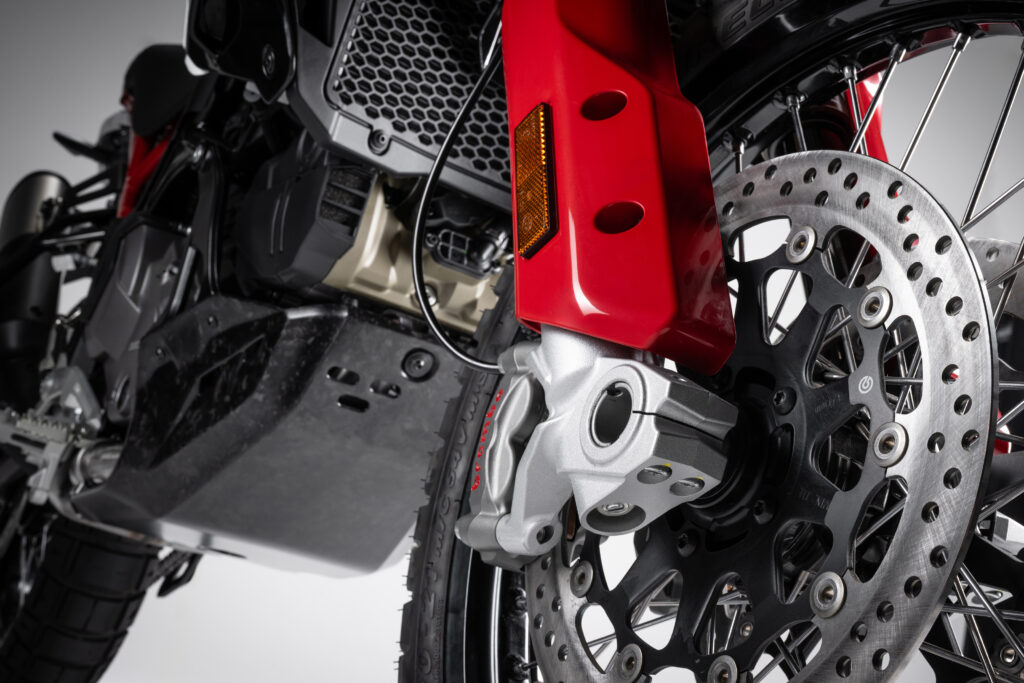

After all, given that this up-specced ‘Rally’ model uses the identical powerplant as the ‘standard’ DesertX that it’s based on (mapping, gearing and exhaust system included, save for a few tweaks in the electronic controls to best suit the different dynamics of the bike), the higher-spec Kayaba suspension componentry represents the biggest difference between the two DesertX versions, and bolsters the Rally model’s off-road chops significantly.

At the international media launch for Ducati’s DesertX Rally earlier this year in Morocco, Transmoto’s Andy Wigan sat down with Ducati’s lead test rider, Matteo Graziani, and asked him to share the backstory about how an MX-derived Kayaba fork and shock ended up on this all-new, very special Ducati DesertX Rally.

*NOTE: Matteo Graziani’s replies below were translated from Italian to English with the help of his colleague, Edoardo Licciardello – Ducati’s Product Communication Specialist.

TM: My Italian isn’t much chop, Edoardo, so thanks for stepping in to translate Matteo’s replies here.

EL: My pleasure, Andy. I will be as accurate as I can. Before we start, and because I know Matteo is modest, let me just start by explaining his role was lead test rider for the DesertX and DesertX Rally models. Matteo is the guy who actually made the requests to the model’s Project Manager, Filippo Marri, about the motocross-derived suspension components that created the significant improvement in the Rally model’s handling behaviour in off-road terrain.

TM: Gotcha. Obviously, Ducati already had a relationship with Kayaba whose suspension components were first fitted to the ‘standard’ DesertX a couple of years ago, and to the Scrambler Desert Sled before that. But the up-specced fork and shock fitted to the DesertX Rally model required a deeper level of collaboration with Kayaba, right?

MG: Yes, we already had the relationship with KYB via Technical Touch (the European subsidiary of Kayaba, which is based in Belgium). But we really wanted to have the closed-cartridge fork on the new DesertX Rally model. When we first communicated that, the Kayaba engineers said that was absolutely not possible. They made the point that this was a motocross fork, which had never been used before on a road-going production motorcycle. So, right from the beginning, we realised there would need to be quite a lot of pushing and pulling for them to agree for us to fit this fork to the DesertX Rally.

TM: Was that initial refusal a matter of principle for the Kayaba guys, or did they think their MX-spec fork would be unsuited to the DesertX Rally?

MG: Well, they simply saw this fork as being designed for – and suited to – motocross use; with a very firm set-up to handle big landings, etcetera. And they were right. That’s why it required a lot of development work to get it behaving correctly on the DesertX Rally – both for demanding off-road use and for road-going applications. We understood from the start that it would require that level of development to be adapted properly to the Rally, but we were committed to that process because we believed it would pay big dividends with the bike’s handling.

When did you first test Kayaba’s closed-cartridge fork on the DesertX Rally?

Along with my team, we started on the development of the fork in January of 2023 – in Sardinia, where the terrain is typically hardpack and very rocky, as well as some other test loops in Tuscany. For that very first test in Sardinia, the Kayaba guys provided us with the fork, along with an email that said we must ABSOLUTELY NOT TOUCH its settings [laughs]. We found its performance was okay, but not exactly what we wanted. So we asked them for some different settings to test. But each time we did that, the answer was always, “Not possible”. Of course, we understood that their aim was to replicate their standard closed-cartridge fork with no variations. That is their sales model. So, it took many conversations, some frustrations, and quite some convincing for them to introduce any of those variations into the fork for us. We were … let’s say, very persistent [laughs].

Why the insistence on a close-cartridge fork from the get-go?

Primarily because we understood the bike’s handling potential could only be properly realised with a more sophisticated fork that used closed-cartridge technology. But also because we wanted to be on par with KTM, which offers a special cone-valve fork on its limited edition 890 R Rally model. It was a commercial strategy for us to offer the same or better fork to what was currently available on the market.

Specifically, what variations in the fork were you requesting from the Kayaba guys?

To get the handling character we were after, it was a step-by-step process over the course of many months and in several different types of terrain. As we hold Ducati’s DRE adventure bike schools in Sardinia, we already had some test loops set up there, and these include a large variety of terrain – from hard to soft, and from slow technical terrain to fast, desert-like tracks. Having that ability to replicate the testing with different settings – on terrain we were familiar with – allowed us to be more efficient with the development process. First, it was obvious that we would need stiffer springs because the Rally weighs more than 200kg with fuel. Second, we wanted the spring inside the cartridge to be softer to give us compliance in the first part of the stroke. The standard fork had a great damping action over big obstacles, but it also had some stiction and was missing the suppleness we wanted over smaller bumps at higher speeds – an issue exacerbated by the firmer fork springs. Once we’d achieved that suppleness at the beginning of the stroke, we then requested different internal oil passages to create the ideal progression in the suspension stroke and ensure we had really good resistance to bottoming. The special coatings – the DLC on the chrome sliders and Kashima Coating on the fork tubes – also played an important role in achieving the overall feel and ride we were chasing. Thankfully, during this process, we were able to get Kayaba’s Technical Touch guys to come along to some of our tests in Italy so they could get an insight into our development process and objectives, and better understand our challenges of getting the perfect compromise and balance between low-speed compliance and high-speed predictability when the bike is being ridden aggressively.

Given that the DesertX Rally – especially when full of fuel – is more than twice the weight of a motocross bikes, it was always unlikely that stiffer springs and bolstered valving would deliver the ride you were after.

Exactly. What we ended up with is definitely not an off-the-shelf component. We needed a very specific solution, and that’s what we ended up with. It required much more than tweaks to springs and valving.

It sounds like the relationship with the Kayaba guys evolved along with the fork’s development. Do you think this collaboration opened the Kayaba guys’ eyes to untapped opportunities in the adventure- and even road-bike markets?

Well, we certainly found a way to work more effectively with each other over the development process. Whether or not that will result in Kayaba getting more involved with adventure or road bikes, I don’t know. You will have to ask Filippo Marri about that [laughs]. I found it interesting how differently that Italians and Japanese approach the development process. Because they are always very polite, they never actually say “no” to you. But I soon came to understand that a slightly awkward laugh from them actually meant no [laughs].

How important a role does the special billet triple clamp play in the overall performance of the fork and front-end feel of the Rally model?

On the one hand, the billet triple clamp is there because the Rally model is a premium product with premium components. But it’s also true that this triple clamp is lighter and more rigid, which increases the feedback and precision of the front-end. It also allows us to integrate the mounting of the high-quality steering damper.

At what stage of the fork’s development process was the steering damper introduced?

We actually used the standard steering damper – available as an optional accessory for the standard DesertX – before upgrading to the Ohlins damper later in the process. That’s because the steering damper does not materially affect the process of developing the fork.

Have we unfairly overlooked the Rally’s shock absorber in this discussion? Obviously, the upgrade to the close-cartridge fork technology is a big step. But in your mind, does the shock deliver the same improvement in performance – aside from the additional 20mm of travel, that is?

I understand what you’re saying. On paper, it appears that the fork gets a much bigger upgrade, but I would say the shock’s performance has been elevated by a similar amount – even though we may not have communicated that as well as we could have. By using a bigger (46mm) piston in the shock body, there is significantly more control over its action. Also, by introducing the high-speed compression damping, you also get a much greater range of damping adjustability and tunability. The remote shock preload adjuster on the Rally’s shock also creates better access for adjustability.

Were the shock upgrades a bit of an afterthought, introduced after the fork development was sorted?

It’s true to say that our development focus was more on the fork, which is correctly regarded as a component that really distinguishes the Rally model from the standard DesertX. But both the fork and shock were developed together to ensure their performance complemented each other, and to retain the correct equilibrium and chassis balance between the front- and the rear-end.

Was the fork and shock in the prototype bike (which Antoine Meo used to great effect in the 2023 Red Bull Erzbergrodeo) any different from what was subsequently used for the production bike?

No. Antoine’s Erzberg race bike used exactly the same fork and shock as the DesertX Rally. Same components, same settings. That Erzberg performance was a clear demonstration of this Kayaba suspension’s incredible capabilities.

What sort of feedback did you get from journalists at the DesertX Rally model’s launch in Morocco?

The feedback we received was very positive at the press launch in Morocco. In fact, many of them were excited about how well the suspension was able to handle jumps and big hits at high speed. So that was very satisfying for us to hear because it is a confirmation that all our hard work paid off. I think the other important thing to point out is that the recommended compression and rebound settings for both the fork and the shock are right in the middle of the range of settings for each. That means there’s margin to adapt them to heavier or more aggressive riders, or to lighter and less experienced riders. And, unlike the case with cheaper suspension, you will find that both the fork and shock are very sensitive to even small changes in these settings.

Thanks for the candid insight into the bike’s development process, Matteo. The thing was very impressive to ride – its suspension in particular!

You’re welcome, Andy. Glad to hear you enjoyed it. We sure had some fun out there in the Agafay Desert!

WHO IS MATTEO GRAZIANI?

Matteo Graziani is one of the most famous Italian Motorally riders. He’s a 59-time Italian champion and protagonist of 30 world rallies. He has participated in the Paris-Dakar Rally three times, managing to finish them all and getting his best placing of 11th Overall and first in category. He is a Federal Enduro Technician, Fast Driving Instructor and works as an instructor in several DRE (Ducati Riding Experience) Academies. Matteo is also an official Ducati tester and test rider, particularly of the Multistrada and DesertX family of models. These days, he makes his experience in maxi-enduro off-road available as Technical Director of the DRE Adventure Academy, supported by a team of three other professional and experienced instructors.

KAYABA SUSPENSION – IN DETAIL…

For more of an insight into the DesertX Rally’s Kayaba fork and shock – including cutaways and internal design details – check out this Ducati-supplied video (the suspension insights appear from around 5:05).

DESERTX SPECS COMPARO – STANDARD VS RALLY

Be the first to comment...